Thermal-insulation bands with thickness 2 or 3 mm laminated with 100 – 200 µm thick LDPE foil are used as a thermal insulation under laminated covers, parquets and other underlaying covers. They soften thermal differences between temperatures of floor and room temperature. They protect floors against damp from the ground. .

a polyethylene foam with constrained cellular structure

| Technical specification | Measure | Value | Measure method by |

|---|---|---|---|

| Material structure | A polyethylene foam with constrained cellular structure | ||

| Thickness | mm | 2 | |

| Density | kg/m3 | 22 | STN 64 7011: 1977 |

| Standard width | mm | 1000 – 1300 | |

| Standard lenght | m | 25 – 300 | |

| Absorbability | Obj. % | Max. 2 | STN 64 5421 |

| Size duration | % | Max. 2 | STN 64 5405 |

| Effect on environment | Ecologically harmless, without freons, 100% recyclable | ||

| Hygienical valuation of the material | Heatlhy and hygienically clean material | Decision af a main hygienic SK | |

| Step noise muting ΔLW | dB | 18,4 | STN EN ISO 717-2 |

| Technical specification | Measure | Value | Measure method by |

|---|---|---|---|

| Material structure | A polyethylene foam with constrained cellular structure | ||

| Thickness | mm | 3 | |

| Density | kg/m3 | 21 | STN 64 7011: 1977 |

| Standard width | mm | 1000 – 1300 | |

| Standard lenght | m | 25 – 300 | |

| Absorbability | Obj. % | Max. 2 | STN 64 5421 |

| Size duration | % | Max. 2 | STN 64 5405 |

| Effect on environment | Ecologically harmless, without freons, 100% recyclable | ||

| Hygienical valuation of the material | Heatlhy and hygienically clean material | Decision af a main hygienic SK | |

| Step noise muting ΔLW | dB | 18,4 | STN EN ISO 717-2 |

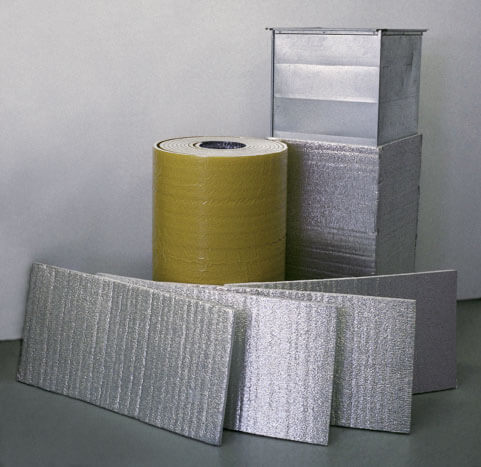

Polypen is a thin, soft and elastic band from polyethylene foam with closed cellular structure. Considering to its 5 and 10 mm thickness it presents an effective sound insulation of floors. This foam allows making floor thickness thinner in compare with classically used materials. Also it is used to decrease step noise in roofs detached flats. For non-absorbability it is ideal to use it in bathrooms and laundries.

a polyethylene foam with constrained cellular structure

Clean the floor before placing the bands.

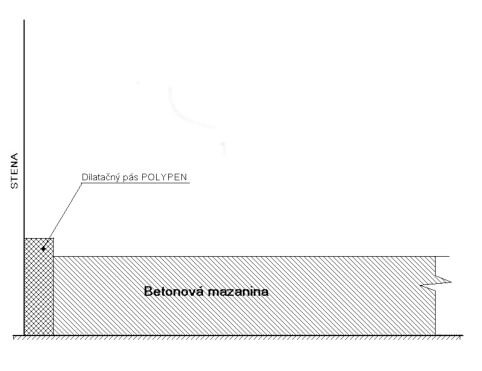

Put the insulation band under concrete smudge. Between concrete and the wall there has to be a dilatation space.

We put the insulation bands abreast.

We roll the bands closely abreast. We can use adhesive band to past together the insulation bands.

When the bands are fixed, we cover the floor according the instructions.

When the band is overlapping the floor, we cut it by knife.

We hide the dilatation space by using the marginal bands.

| Technical characteristics | Measure | Value | Measure method by |

|---|---|---|---|

| Material structure | A polyethylene foam with constrained cellular structure | ||

| Thickness | mm | 5 | |

| Density | kg/m3 | 26 | STN 64 7011: 1977 |

| Standard width | mm | 100, 110 | |

| Standard lenght | m | 50 | |

| Absorbability | Obj. % | Max. 2 | STN 64 5421 |

| Size duration | % | Max. 2 | STN 64 5405 |

| Effect on environment | Ecologically harmless, without freons, 100% recyclable | ||

| Hygienical valuation of the material | Heatlhy and hygienically clean material | Decision af a main hygienic SK | |

| Step noise muting ΔLW | dB | 16,9 | STN EN ISO 717-2 |

| Technical characteristics | Measure | Value | Measure method by |

|---|---|---|---|

| Material structure | A polyethylene foam with constrained cellular structure | ||

| Thickness | mm | 10 | |

| Density | kg/m3 | 27 | STN 64 7011: 1977 |

| Standard width | mm | 1000 – 1300 | |

| Standard lenght | m | 25 – 300 | |

| Absorbability | Obj. % | Max. 2 | STN 64 5421 |

| Size duration | % | Max. 2 | STN 64 5405 |

| Effect on environment | Ecologically harmless, without freons, 100% recyclable | ||

| Hygienical valuation of the material | Heatlhy and hygienically clean material | Decision af a main hygienic SK | |

| Step noise muting ΔLW | dB | 18 | STN EN ISO 717-2 |

permanently elastic filling of dynamically stressed expansion gaps characterized by the ability to eliminate the negative effects of thermal expansion of building materials. The special construction of the strips prevents the leakage of cement water from the concrete into the external wall or open areas. The permanently flexible filling of expansion joints reduces the transmission of noise from floors to peripheral masonry. The bands are produced in various widths and thicknesses. The material is excellent flexible, permanently flexible and easy to process.

Prevedenia podľa želania zákazníka je možné dohodnúť si s výrobcom.

The self-adhesive layer is designed for the connection of heat-insulating boards and bands POLYPEN with metal, ceramic, glass or plastic base surfaces. POLYPEN thermal insulation boards and strips with self-adhesive can be applied to surfaces whose permanent temperature ranges from 0 ° C to +80 ° C. Applied thermal insulation boards and bands POLYPEN must be protected from direct weathering.

The adhesive force is not caused by the reaction of the adhesive to the substrate, nor by the drying of the adhesive, but only by perfect contact of the adhesive and the substrate. The adhesive force is greater the flatter and smoother the base surface and the greater the pressure the pressure-sensitive adhesive is pressed against the base surface. Boards with a self-adhesive layer must be glued to the substrate fully. Partial attachment (points, stripes and others) is insufficient. Use fasteners or special metal brackets to fasten boards over 20 mm thick to vertical surfaces and ceilings.

The active life of the self-adhesive layer is 6 months from the date of manufacture.

Tepelno-izolačné dosky a pásy POLYPEN skladujte v suchom prostredí a v pôvodných obaloch. Skladovaný materiál chráňte pred extrémnymi teplotami, priamym slnečným žiarením a pred nečistotami.

The vapor-reflective bubble wrap combines the properties of vapor-tight film, thermal insulation and reflective effects. The foil is made by laminating a reflective aluminum layer onto a bubble foil. The aluminum layer reflects up to 90% of the thermal radiation back into the room. The reflective layer together with the air cushions of the bubble wrap and the air gap between the film and the inner lining act as an additional insulation replacing up to 50 mm of mineral wool. The application of the foil removes the thermal bridges between the insulation and the rafters. The economic return of the foil is 1-2 years. When used as insulation under floor heating, it ensures that the radiant heat from the heating does not leak into the floor but into the room

bubble foil laminated with aluminum foil DUPLEX foil. DUPLEX film is composed of 12 µm thick reflective foil of metallised polyester (PET) and 17 µm thick low density polyethylene (LDPE) foil.

Versions according to the customer’s wish can be agreed with the product.

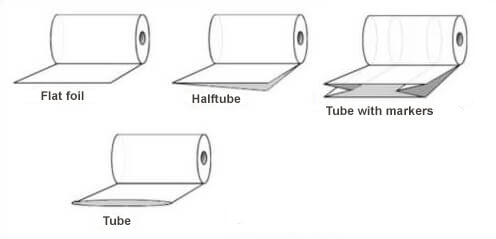

We offer LDPE foil in following versions: tube, tube with markers, halftube, halftube cut right, left and flat foil. It is used as a steam-block and insulation against damp.

| Thickness: | 50µm – 200 µm |

|---|---|

| Maximal width: | 1200 mm |

| Marker´s width: | 700 mm |

| Colour: | transparent or black |